Large uncertainties mean it is not clear which electrification pathway will prove most economical. Development of multiple pathways should, therefore, continue. These include statically charged battery electric vehicles (BEVs), fuel cell electric vehicles (FCEVs), plug-in hybrid electric vehicles (PHEVs), and electric vehicles designed for a combination of plug-in and electric road system (ERS) supply. The largest uncertainties relate to the cost of hydrogen, electrical supply, and battery life. Consequently, efforts should focus on the techno-economic analysis of these parameters.

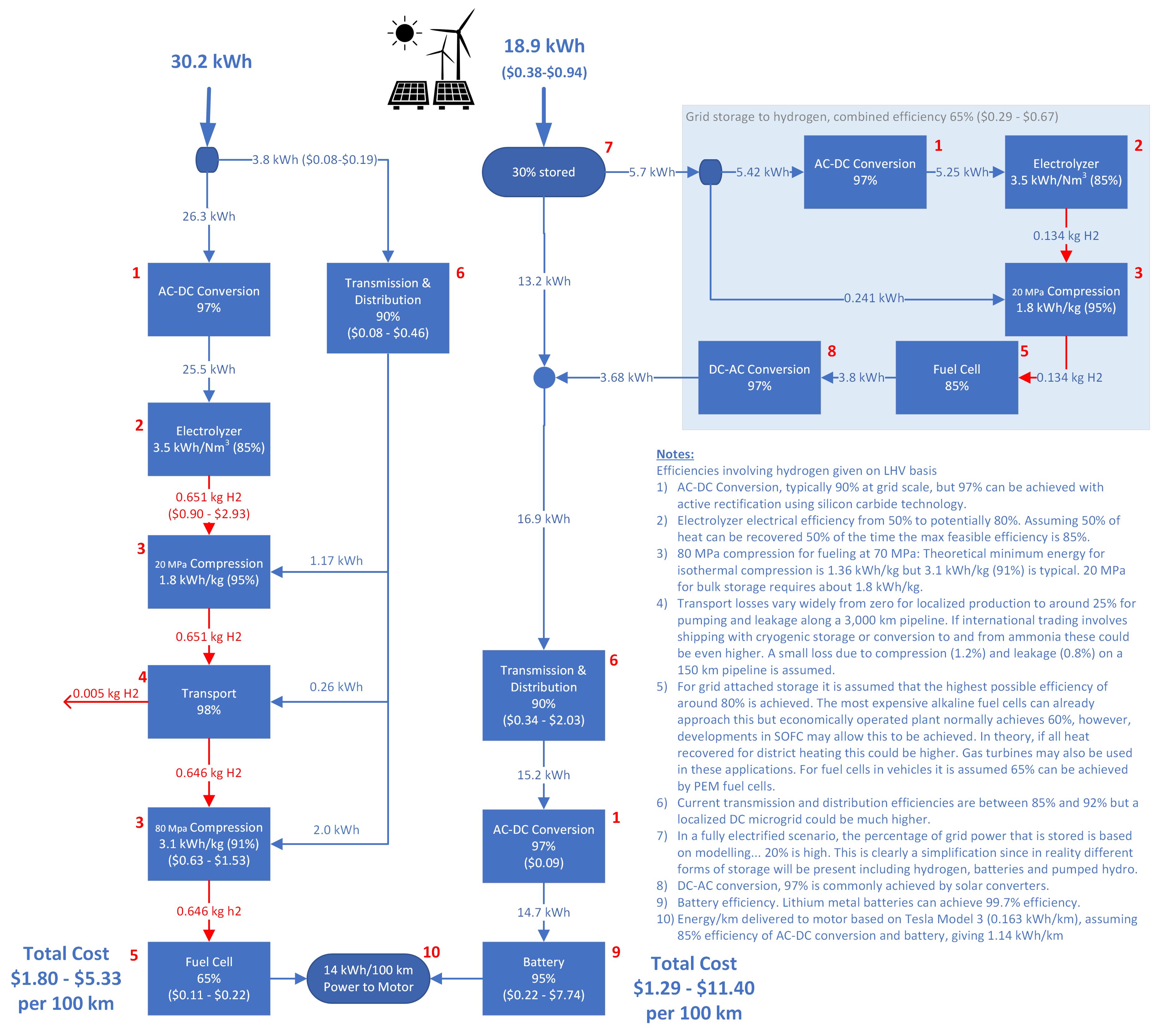

The economics of green hydrogen will depend on electrolyzer and fuel cell costs, life spans and efficiencies, distribution and storage costs, the time-based cost of renewable electricity, and the extent to which more efficient electrolyzers with heat recovery methods can be used. Green hydrogen must first be allocated to where there is little alternative. For example, existing industrial feedstock uses, aviation, steel production and seasonal energy buffering in the grid. Most of the surplus electricity is likely to be consumed my these uses, meaning that additional hydrogen production for road transport will require additional generation capacity.

Uncertainties in electrical distribution costs largely reflect different geographical regions. The unit costs are known for power converters and cabling associated with transmission and distribution. Region-specific cost models are needed, especially for ERS. An improved understanding of vehicle battery life is vital in evaluating the cost of battery and hybrid vehicles. For ERS, it is critical to understand how battery life will be affected by frequent cycling and the extent to which battery technology from hybrid vehicles can be applied. ERS must also now be tested on busy public roads to establish maintenance costs.

The full report is available from SAE International.