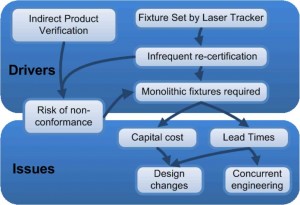

Design verification in the digital domain, using model-based principles, is a key research objective to address the industrial requirement for reduced physical testing and prototyping. For complex assemblies, the verification of the design intent and the associated production methods is currently fragmented, prolonged and sub-optimal, as it is based on the sequential consideration of various aspects in the digital and physical domains using a range of systems.

This paper describes a novel hybrid design verification methodology that integrates model-based verification analysis with the measurement data and plans derived from the physical testing of prototype assemblies, in order to facilitate the early verification of complex designs from the perspective of satisfying key assembly criteria.

Authors

Maropoulos, P.G., P. Vichare, O. Martin, J.E. Muelaner, M. Summers, and A. Kayani

Published in

CIRP Annals – Manufacturing Technology, 2011

Volume and page number information

60(1)

DOI

10.1016/j.cirp.2011.03.097.

Download