assessment of instruments. An important aspect of this work is uncertainty

evaluation. Jody Muelaner has led projects at the University of

Bath to address this need.

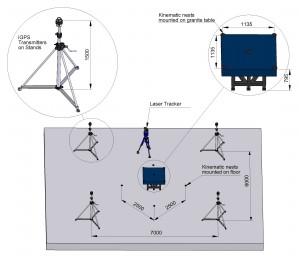

iGPS Capability Study

The indoor GPS (iGPS)

system is a radically new form of coordinate measurement instrument designed to

provide a factory wide measurement infrastructure. Work was carried out with the

National Physical Laboratory to understand the performance of this system.

- iGPS Capability

Study, an NPL Report. 2010 - Study of the Uncertainty of Angle Measurement for a Rotary-Laser Automatic Theodolite (R-LAT)

in IMechE, Part B: JEM, 2008

Estimation of Uncertainty in Three Dimensional Coordinate Measurement by Comparison with Calibrated Points.

in

Measurement Science and Technology, 2010- Verification of the Indoor GPS System, by Comparison with Calibrated Coordinates and by Angular Reference.

in Journal of Intelligent Manufacturing, 2010 - iGPS – An Initial Assessment Of Technical And Deployment Capability

at ICMEN, 2008 - Verification Of The Indoor Gps System By Comparison With Points Calibrated Using A Network Of Laser Tracker Measurements,

in DET 2009

NGCW State of the Art Review

The Next Generation Composite Wing (NGCW) project is a £100M initiative led by Airbus to revolutionize aircraft wings.

Within this project Jody Muelaner led a

review of metrology technology

consisting of over 650 pages written by contributors from several

universities as well as the NPL.

Other Relevant Publications

- Large Scale Metrology in Aerospace Assembly,

at DET. 2008